VERSATILE AUTOMATED WELDING FOR STRUCTURAL & MISC-METALS

BeamWELD offers a streamlined approach to welding structural steel, allowing you to load pre-fitted beams and let the system handle the welding tasks with precision and speed. With multiple configurations and advanced programming software, BeamWELD supports both offline and on-control automated programming. It also allows for manual adjustments to weld settings and locations. The system autonomously optimizes each weld, making robotic welding profitable even for single-piece production runs, which traditionally required high volumes to be cost-effective.

5 Simple Steps:

Load Workpiece: Place the steel beam or weldment into the system.

Load CAD File: Import the CAD file from Tekla, SDS2, or another compatible software.

Scan Workpiece: The robot quickly scans the workpiece to verify its position.

Assign Weld Data: Apply pre-established weld data to the designated weld locations, or modify weld data if needed.

Start Welding: Initiate the welding process.

VERSATILE WELDING AUTOMATION WITH 3-4X MORE PRODUCTIVITY.

Endless Supported Connection Types

Versatile Welding Automation

Scan Beam or Weldment Location: Precisely locate the workpiece.

Auto-Generate Path Data: Use CAD models or full scans to create paths.

Create Welding Paths: Choose between automatic or manual path creation based on joint dynamics.

Match Welds with Procedures: Ensure correct welding procedures are applied.

Plan Movements Between Welds: Automate or manually adjust weld order.

Incorporate Torch Maintenance: Includes functions like nozzle cleaning for consistent performance.

Export Directly from Tekla, SDS2, & Other CAD Softwares

Seamlessly export .ifc weldment assemblies from BIM softwares and bring them directly into BeamWELD’s Intuitive programming software.

If your workflow comes from RailBLAZER or FlexLAZER fiber laser cutting machines, simply import .step files from CAD softwares for streamlined operation.

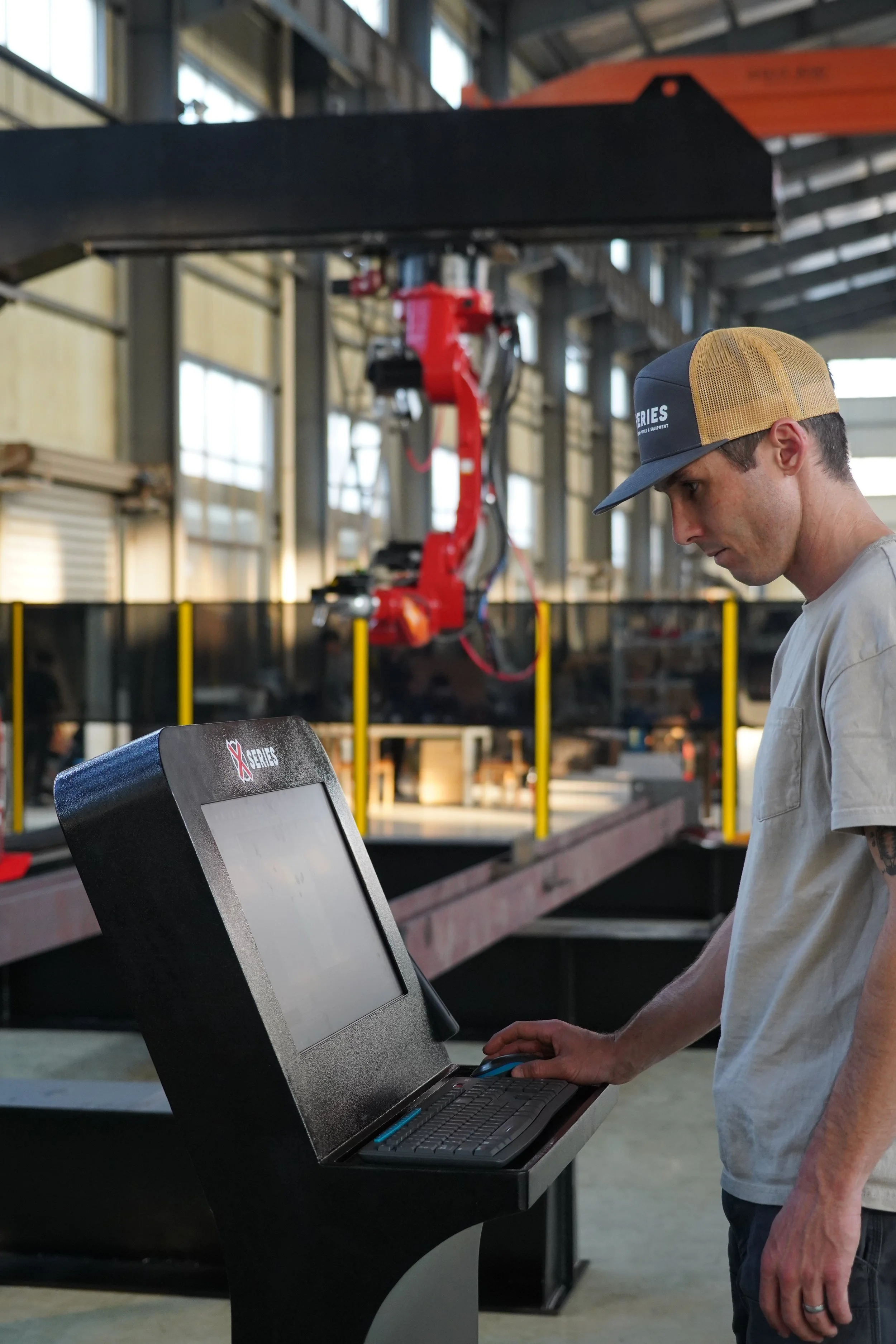

Intuitive 3D Graphical Programming & Simulation:

Digital Twin Technology allows for seamless operator interaction and provides real-time feedback for easy visualization and adjustments.

Auto-Programming with Manual Intervention:

Automates programming while allowing for quick manual adjustments of the workpiece.

Quickly Add or Modify Welds:

Enables on-the-fly adjustments to weld locations, weld parameters. Operators can add, delete, & even modify welds on the fly allowing for maximum flexibility.

Line Laser Seam Detection

Automatic Seam Detection: Precisely identifies seam locations on the workpiece.

Fit-Up Deviation Control: Monitors and manages deviations in fit-up to ensure accuracy.

Adjustable Tolerances: Software allows for setting custom tolerances for seam detection.

Reliable Weld Quality: Enhances weld consistency by ensuring seams are correctly aligned with the weld program.

Suitable for Well-Lit Environments: Effective even in brightly lit workspaces, maintaining obtimal performance.

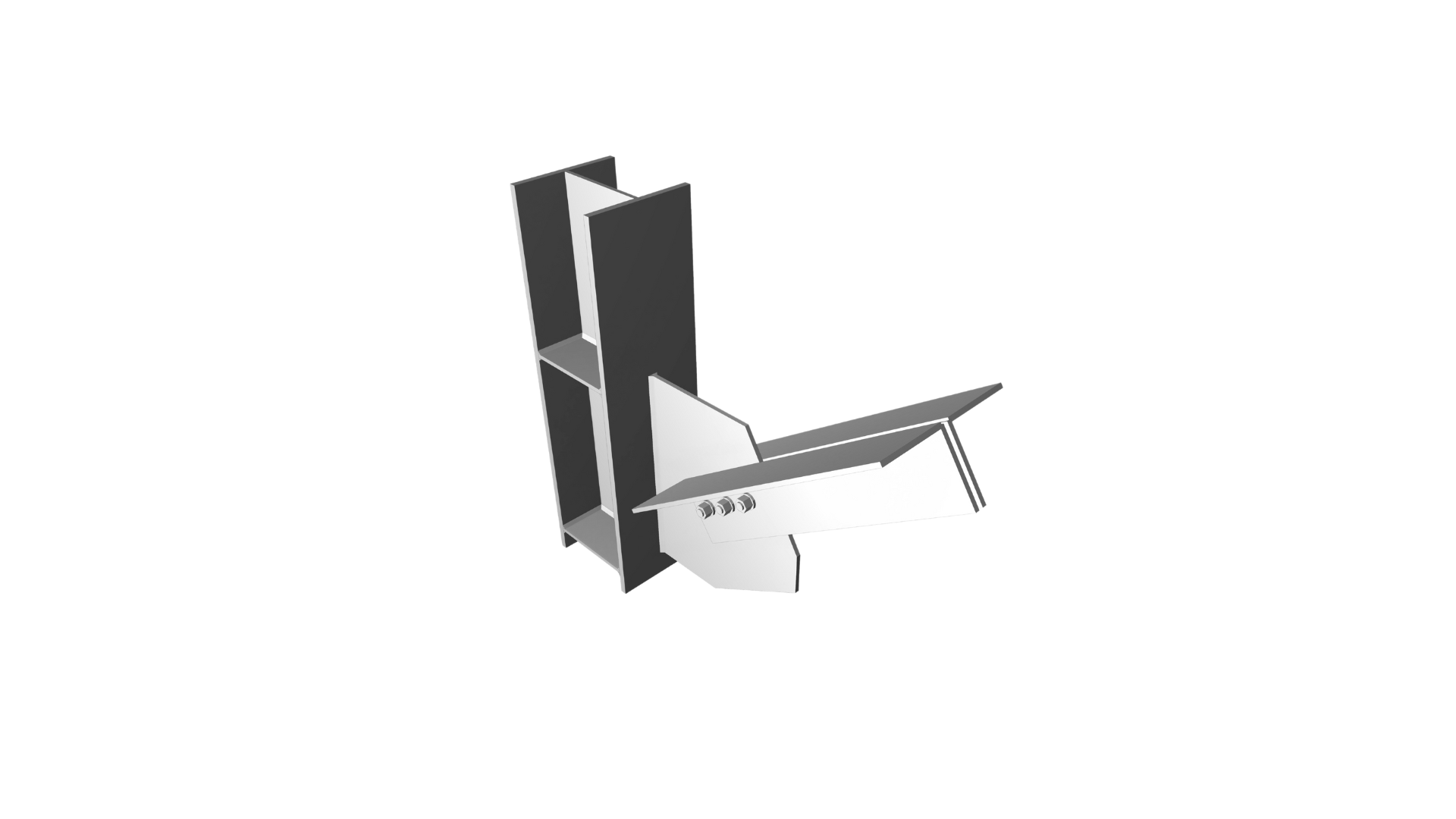

BeamWELD x Pro (8-Axis)

Specs:

BeamWELD x MAX (9-Axis)

Specs:

BeamWELD x ECO (7-Axis)

Specs:

X-WELD

Specs: